Wind Tunnel Frame - Build Plan

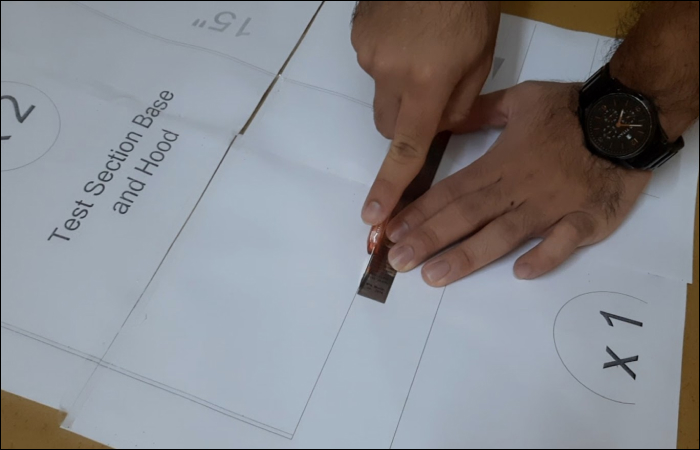

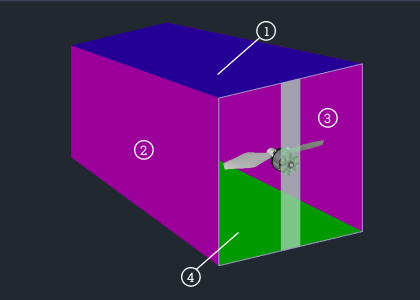

Building the frame is a fairly simple process. It starts with a printable blueprint plan, which you will use to trace and cut the components of the wind tunnel sections. The cardboard (or foamboard) pieces are joined together, which forms a the windtunnel. Besides this, only a few components remain to have a completely functional windtunnel.

| Item | Material | Quantity |

|---|---|---|

| 1 |

Cardboard Wall - Single Wall Board Flute Style - Corrugated Thickness - 4.8mm (Flute A) Paper - Kraft |

4 sheets - 841 mm x 1188 mm (A0) 3 sheets - 594 mm x 841 mm (A1) Total Required Area - 2375 sq. inches |

| 2 | Hot Glue Gun Glue Stick |

X 1 |

| 3 | Thumb pins | X 8 |

| 4 | Exacto-Knife OR Box Cutter |

X 1 |

| 5 | Metal Ruler/Scale (30 cm) | X 1 |

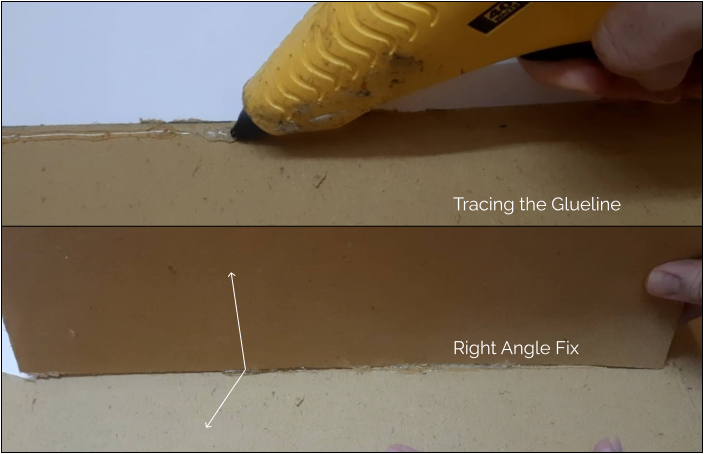

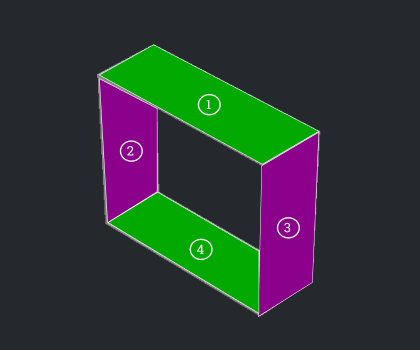

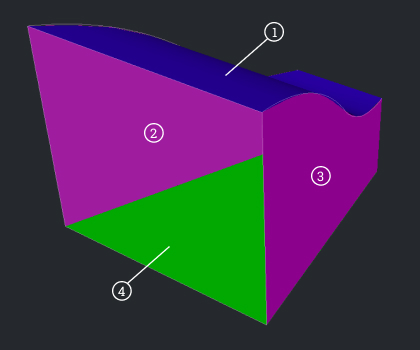

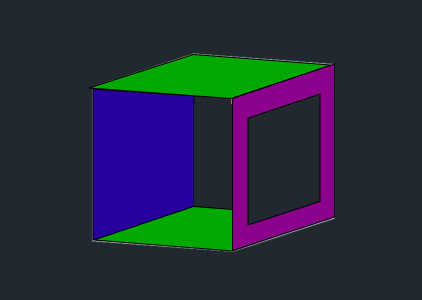

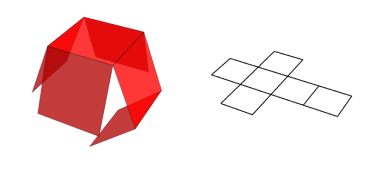

After cutting each of the section’s sides on the 2D board, we join them to form the 3D figure. Exactly like the adjacent image, where the 2D squares are cut and stuck at right angles from each other to form a 3D cube.

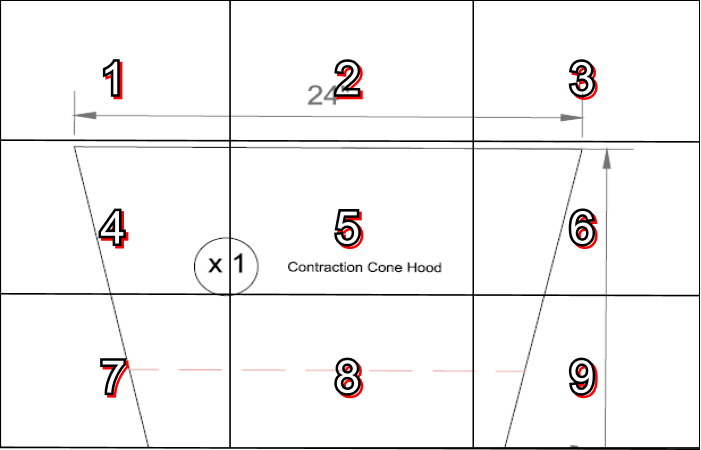

Now, the 2D shapes required to build the 3D sections of the windtunnel aren’t easy to make. This is why the full scale plans for each section are provided in the build plan below.

Some of the dimensions of the pieces, however, are several inches larger and wider than the A4 sheet size, and only fit on A1 sheets.

To make this accessible to everyone, though, the option of joining A4 sheets to stitch together the full-scale diagram is facilitated in the build plans.

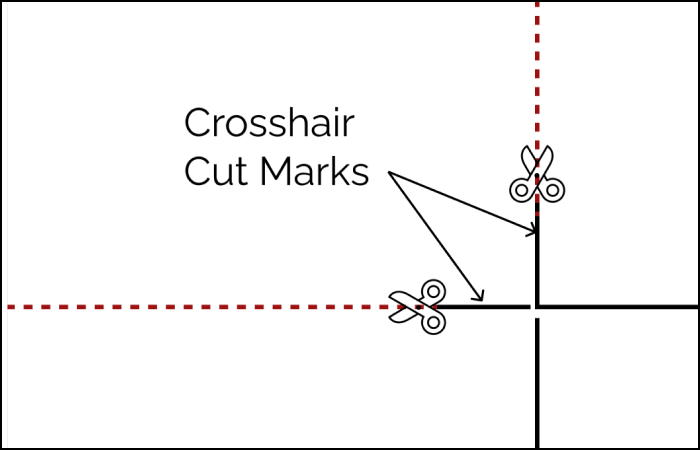

The steps from printing to building all the section frames are common in procedure. They are as follows:

3D Cube from a 2D Board